This Excel spreadsheet calculates the flowrate from the pressure drop across a gas orifice meter with the equations defined in ISO 5167.

Orifice meters use the pressure loss across a constriction (that is, the orifice plate) in a pipe to determine the flowrate. While orifice meters are cost effective, they have several disadvantages.

- The relationship between flowrate and pressure is non-linear,

- accurate values of the physical parameters are required,

- and high Reynolds numbers (>104) are required for the greatest confidence in their accuracy, and the resulting pressure drop can be significant.

Accordingly, orifice meters are only used with the pressure drop is not critical, and accuracy is around 2% at best.

These are the equations implemented in the spreadsheet (as specified in ISO 5167)

|

| Gas Orifice Meter Equations in ISO 5167 |

The notation is given below

- C is the discharge coefficient (only valid for the three standard tap positions given below)

- Re is the Reynolds number

- L1 and L2 are the upstream and downstream tap positions (m)

- P1 and P2 are the upstream and downstream pressures (Pa)

- D1 and D2 are the pipe and orifice diameters (m)

- V is the gas velocity in the pipe (m s-1)

- ρ is the gas density (kg m-3)

- μ is the gas viscosity (Pa s)

- M is the molecular weight

- Y is the expansion coefficient

- Z is the gas compressibility factor

- K is the specific heat ratio

- R is the gas constant (8314 J kg-1 k-1)

- Ao is the cross-sectional area of the orifice (m2)

There are three standard tap positions that determine the values of L

1 and L

2, as illustrated below. For corner taps, L

1 = L

2= 0, for D-D/2 taps L

1 = D

1 and L

2= D

1/2, and for flange taps L

1 = L

2= 1 inch.

|

| Tap positions in ISO 5167 |

The equations use the ideal gas law to calculate the gas density (you could override this with your own value), and are only valid for pipes with internal diameters from 50 mm to 1000 mm, and for pressure ratios greater than 0.75.

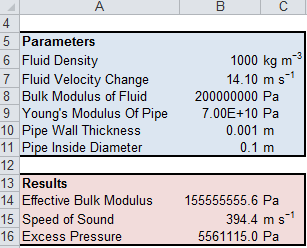

This is a screen grab of part of the spreadsheet.

The calculation is iterative: you need Re to calculate C, you need V to calculate Re, but you need C to calculate V. Excel's Goal Seek functionality is used to iteratively solve the equations for the flowrate. This process is automated with a button - just fill in the parameters, click a button, and some VBA initiates Goal Seek with the correct settings

The spreadsheet provides an initial guess value for Re. This is used to

calculate C and V. V is then used to calculate Re. Excel's Goal Seek

varies the guess value of Re until it matches the calculated value of

Re.

By carefuly altering the equations (and the parameters used by Goal Seek), you could also solve for any other variable - for example, you could find the pressure drop for a specific flowrate (let me know if you need help in implementing this).

You'll find a spreadsheet that models a

liquid orifice meter here.

Visit

http://excelcalculations.blogspot.com regularly for more free engineering spreadsheets.

Download Excel Spreadsheet to Calculate Flowrate in a Gas Orifice Meter (ISO 5167)